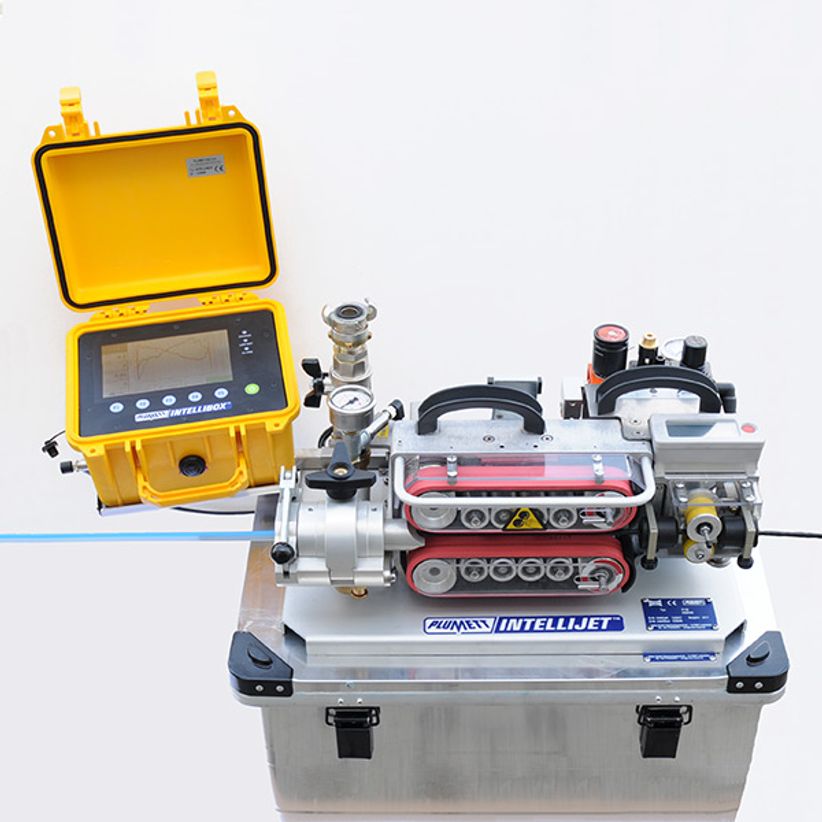

IntelliJet™ - now in Series-Production

The first semi-automatic cable blowing machine with installation assistant and electronic blowing data recorder.

The new IntelliJet™ is a pioneering, intelligent cable blowing system that facilitates the laying of fibre optic cables for the machine operators and improves installation quality.

Cable layers as well as customers benefit from these improvements.

At the heart of the innovation is the measurement and control of the pushing force, which is transferred onto the cable by the belt drive system. The pushing force is constantly verified against the maximum permissible value, which is determined through the crash test. In the future this force will be specified on the cable data sheets. A second assistant monitors the cable slippage. Both assistants indicate critical values and when exceeded the machine stops. Cable damages are prevented.

A clear blowing log with an electronic data transfer completes the new system. The new IntelliJet™ not only meets the minimum requirements for automatic logging of Deutsche Telekom in Germany, but is also a major step forward towards the future requirements for automated cable installations. Existing MiniJet™ P01 and P02 can be upgraded to IntelliJet™.

The main benefits for cable layers are:

The two blowing assistants indicate critical operating conditions and stop the blowing process before damage to the cable occurs. Time savings for the installers and order processing thanks to automatic data logging, archiving and electronic transmission. The logging of blowing parameters can provide evidence of problems in duct routes. The handling on the construction site is simple and nearly identical to current work with the MiniJet™.

Customers also benefit from the use of the IntelliJet™:

The automation of the blowing process will improve blowing performance and quality and reduce damage to cables, which increases the efficiency of FTTx projects. Precise and clear logging of the agreed blowing performance facilitates the error detection, financial settlement and data archiving. If damage to cables occurs at a later stage, the original blowing log provides a reference for the blowing-out capability of the cable and can thereby reduce repair costs.